This is Kubota from Adan Staff.

The weather has suddenly turned autumnal.

It's autumn, the season of appetite and the season of art, so I resumed the renovation of a diamond ring, which had been in progress at a leisurely pace (^^).

Previous process is here≫https://adam.co.jp/?p=11927

The broken arm had been rebuilt and was on the verge of being brazed (welded).

Today we start with a story about diamond selection.

The "4Cs" you will surely hear when looking for a diamond ring

Carat Carat

Color Color

Clarity Clarity (inclusions)

Cut Cut

The value of a diamond varies according to these four grades.

≫ For more information: http://www.adam.co.jp/diamond/

At Adan, we place particular emphasis on "cutting.

Since this ring is very important to me, I also chose a 3EX H&C ring with a good cut grade.

A good cut is like maximizing the brilliance of the diamond,

Symmetry" is also emphasized in order to achieve ideal proportions.

A beautifully cut diamond can be seen with a special loupe...

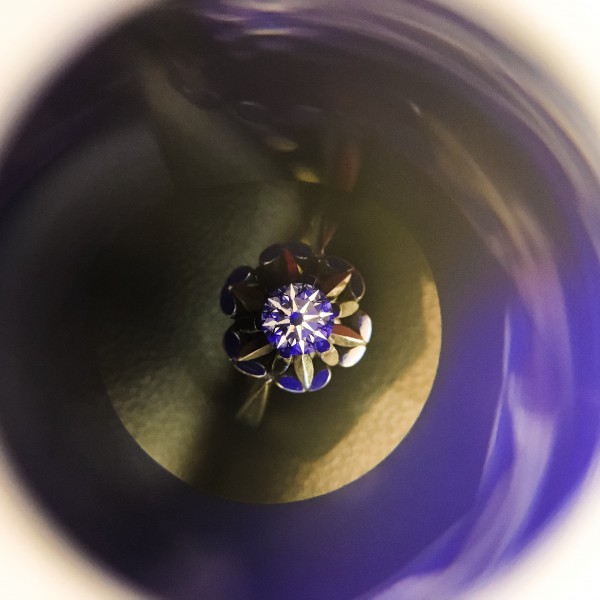

The H&C, or heart and cupid, pattern can be seen in the reflections of the cut surface!

Above is the face of Cupid's arrow.

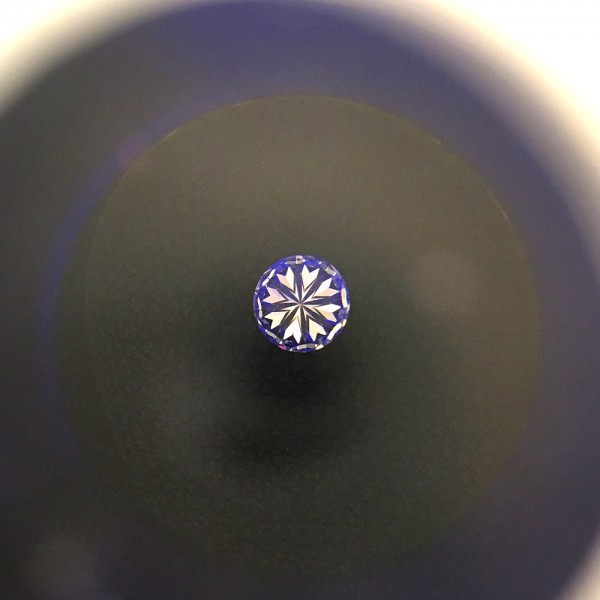

And on the reverse side are eight hearts...!

The back side cannot be seen after it is turned into a ring, so it is a rare sight that can only be seen before processing.

Once you have been soothed by the beautiful loose pieces, you can resume processing the ring.

Brazing is performed to weld the ring's stone seat and arm.

White gold, which has a slightly lower melting point than the ring's matrix, called a low agent, is poured into the gaps to join them.

I was so focused on it that I forgot to take a picture,

It was attached safely!

The plating that was probably originally on the stone seat discolored due to heating, making it difficult to finish, but we managed to make it shiny!

Whew, I was nervous.

Clasp the stone and you are done!

I will tell you the rest next time.